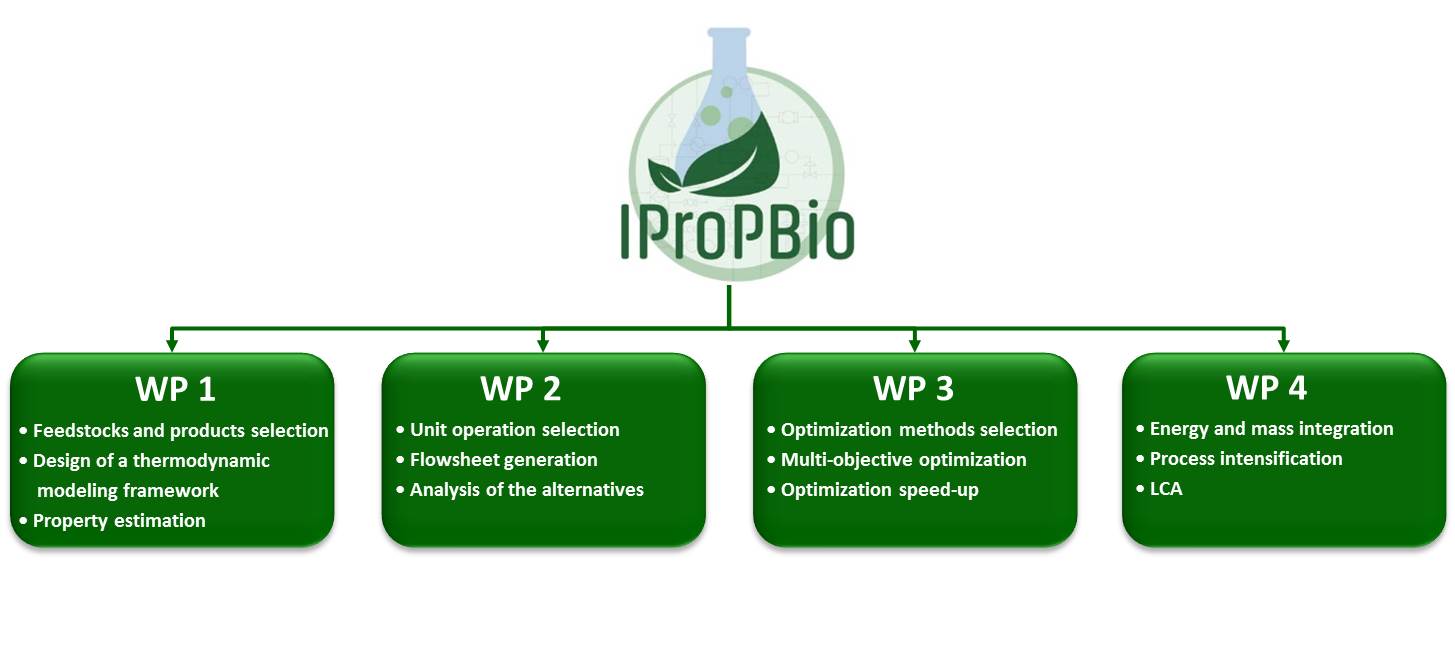

The project is divided in six specific objectives divided in four work operative packages (WP) as reported in the diagram. To each work package is assigned a main responsible for the coordination of the work and the tasks among the participants.

Specific objectives:

Specific objectives:

- Selection of alternative feed stocks to generate a variety of high added value bio-products. The selection of alternative feedstocks for the “smart” BioRef” is a key factor which influences the processes and equipment needed for their transformation, the products obtainable and their functional properties, as well as its impact on the environment. The selection of alternative feedstocks will be based on thorough analysis of the waste biomass feedstocks available in the partner´s countries.

- Design, validation and implementation of a thermodynamic framework (TMF). The proper design of biorefinery systems requires the application of a next generation TMF that overcomes the existing challenges, with the potential to improve the accuracy and provide high predictive ability and reliable description of the thermodynamics and kinetics of the processes involved at a wide range of operating conditions. Thus, the TMF will have a large positive impact on higher level modelling, improving the quality of the results and the evaluation of the different process configurations. The structure of the TMF is modular and involves the following three elements: 1. Thermodynamic models for mixture properties; 2. Model-independent routines, namely methods, algorithms and numerical techniques for performing stability analysis and solving the phase and chemical equilibrium relations; 3. Library of thermo-physical properties of pure substances and methods for estimating the missing ones.

- Estimation of properties for integrated process and project design. This specific objective addresses another key factor for the realization of IProPBio, as the property values of the selected feedstocks and/or their mixtures are needed in the modelling of the transformation processes, in the formulation of product portfolios and in the evaluation of the pollutants generated. In the quest for property values, experimental data are preferred, so a critical review of published data is essential. However, experimental data are scarce and usually limited to pure compounds, while the real objects are mixtures. For many pure compounds and their mixtures, the needed property values (e.g., critical properties) cannot be measured for different reasons. In such cases, published prediction methods, if they exist, have to be critically analyzed, and eventually adapted to the particular context of their application. If published prediction methods are not available or applicable, new estimation methods have to be developed.

- Systematic synthesis of process alternatives. This objective addresses the definition of a novel methodology able to generate all feasible flowsheets related to the purification of the products identified in the objective 1. The development of the methodology is a key element of the innovative research as it avoids any random generation attempt that could potentially bring to consider an incomplete set of alternatives. Systematic synthesis procedures are considered also beneficial to speed up the design and optimization steps.

- Multi-objective optimization problem. Process integration and intensification of multiproduct portfolio biorefineries involve several numerical challenges. For example, the mass and energy integration is fundamental to reduce waste streams, to minimize energy consumption and to reduce operating costs. The trade-off between purification effectiveness and cost in separation systems is determined by the operating conditions and design variables of the separation technologies. Therefore, from a mathematical perspective, the identification of the best configuration can be formulated as a multi-objective optimization problem where several optimization targets are in conflict. This multi-objective optimization problem includes both continuous and discrete design variables that are also subject to several constraints. This type of optimization problems is present in several stages of the conceptual design and it requires the use of proper optimization strategies and process intensification methodologies for its resolution.

- Process Integration and Life cycle analysis of different target products. Process integration involves setting targets for best theoretical performance of a process, and solves them for various alternative processes based on constraints imposed by practical considerations. Energy integration and mass integration (primarily water) are two areas where these integration principles can be applied. Life Cycle Assessment offers a methodological framework to analyze the effectiveness of a proposed process. It has four stages: goal and scope definition, inventory assessment, environmental impact assessment and analysis of results. In this project, the novelty is reached analysing the results obtained for the alternatives obtained applying the inherently safer process design and process integration, using a life cycle framework to provide a comprehensive approach towards problem solving.